Services

Ultrasonic welding

Ultrasonic welding: strong and precise connections

Quality

Ultrasonic welding is a technology that uses high-frequency sound waves to fuse materials together. It is a fast, efficient and reliable method that is particularly suitable for joining plastic parts.

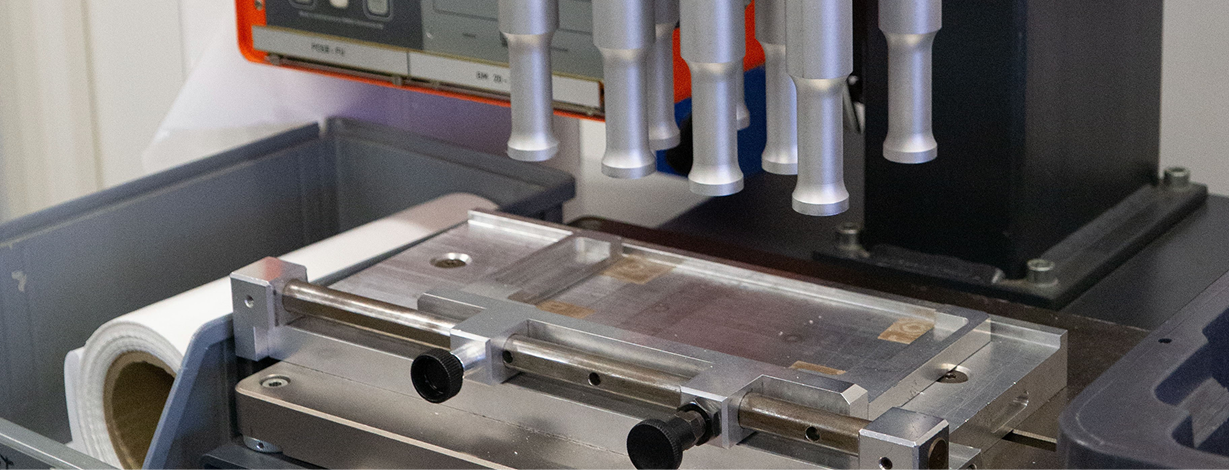

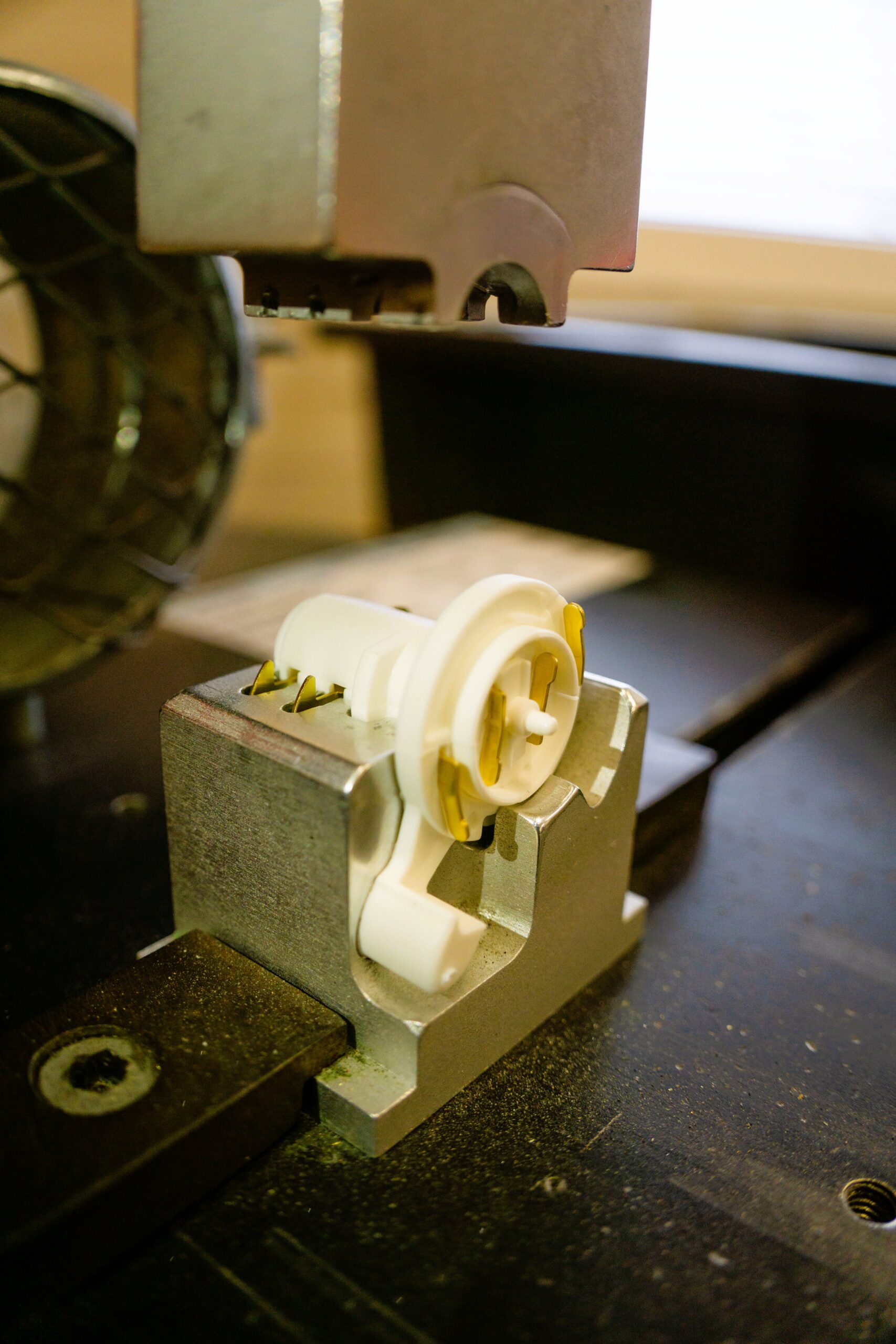

- Configuration: for each product, a suitable cell is designed and a tuned sound head is used to ultrasonically weld the corresponding product; the appropriate parameters (amplitude, time, pressure, speed, holding time) for each product are entered into the generator.

- The converter converts the electrical energy generated by the generator into mechanical vibration, the booster amplifies the vibration and the horn/sonotrode, depending on the design, either amplifies the vibration or transfers it to the product to be welded.

- Sound waves are guided through the contact surface of the parts, where they generate friction and thermal energy.

- The heat generated melts the contact surfaces of the materials, allowing them to fuse together.

- After the ultrasonic effect has finished, the parts cool and a strong and durable weld bond is formed.

Benefits

Ultrasonic welding has a number of advantages that make it a good choice for joining different materials:

Speed

ultrasonic welding is a very fast process that allows high production volumes to be achieved in a short time.

Accuracy

this technology ensures accurate, high-quality welds that are durable and aesthetically pleasing.

Minimum distortion

ultrasonic welding generates heat mainly at the interface, which reduces the risk of distortion of the base materials.

Energy efficiency

compared to other welding methods, ultrasonic welding is more energy efficient as it does not require high temperatures or additional materials.

Environmental friendliness

ultrasonic welding is a clean and environmentally friendly method as it does not produce harmful emissions or waste.

Areas of application

Ultrasonic welding is a modern and efficient technology that provides strong, precise and fast joints to a wide range of materials. Its advantages make it an excellent choice for a wide range of industries where both quality and productivity are important.

Ultrasonic welding is widely used in various industries, such as:

welding plastic parts (e.g. car parts, medical supplies, packaging).

connecting electrical equipment and components.